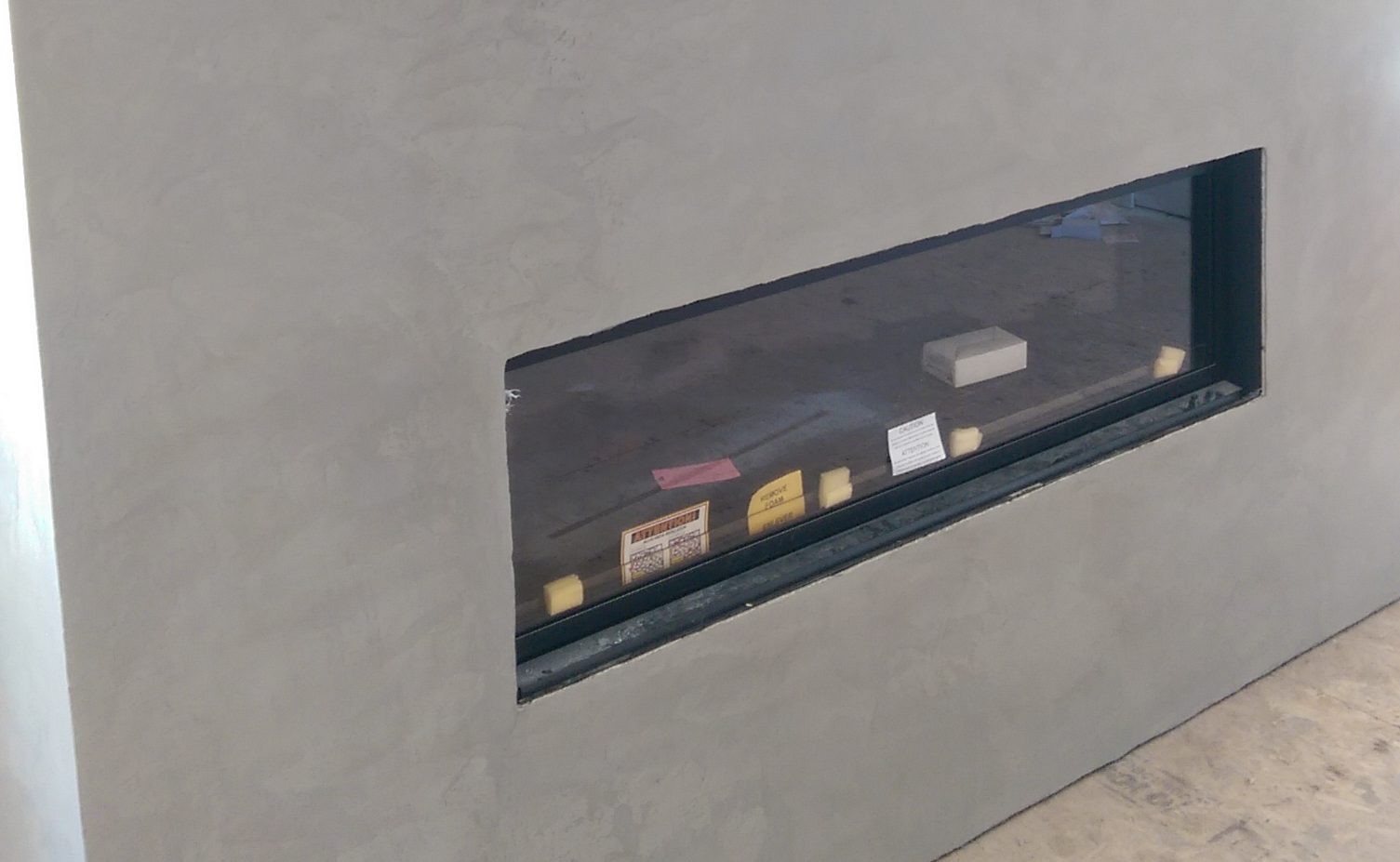

We were asked to produce a polished concrete look for this fireplace in a new custom home in Maple Ridge. The backing substrate is Durock cement board, and we applied a special concrete bonding agent to the cement board prior to applying any tape or plaster. As you can see in the photos, all the external angles were applied with tile adhesive, and the entire structure was first taped in with cement board joint tape, and then alkaline resistant fiberglass stucco mesh was embedded into the entire first coat to further reduce cracking.

Fireplaces like these can be done on any substrate however; and if they are a new structure, drywall or cement board are good options along with bricks and blocks being great alternatives. If you have an existing fireplace then we can easily cover over the entire structure with our plasters without having to do any major renovations.

To create depth and a deeper tones this fireplace has olive oil soap added and a wax to create the final look. Two coats of Meoded’s Golmex concrete plaster were used to create this custom one of a kind look. This finish can be made more or less shiny, can be sanded once dry and or made to look like form board concrete, concrete walls with holes in it, or anything in between. As always with our plasters and systems, paint is just the beginning!

Hello Love this look,

Do you happen to have the”name: of the grey color used ? We are getting ready to plaster:)

Hi Sandra, I’m sorry for the late reply as i didn’t see your comment. This is a product called Golmex, and it is a mix of lime, cement, marble powder and silica sands that produce a concrete look. The product itself is not tinted and has its own characteristic color.