Our Process

Relationships

We know how important our clients’ projects are to them, and we strive to establish a strong relationship with open communication to achieve the most pleasing result. There are limitations to installations, and occasionally it may become clear that our system will not meet a client’s expectations. In this case, we are honest in discussing the benefits and limitations of our finishes.

Curiosity

We want to know about our client’s brand, their passion, and how they fit into the local and global communities. We want to know where the product is being installed, the substrate options – be they new or existing – and why a particular finish is desired for the project. With this understanding, we will then request texture, color, and design inspirations to allow us to craft the plaster and finish.

In the Lab

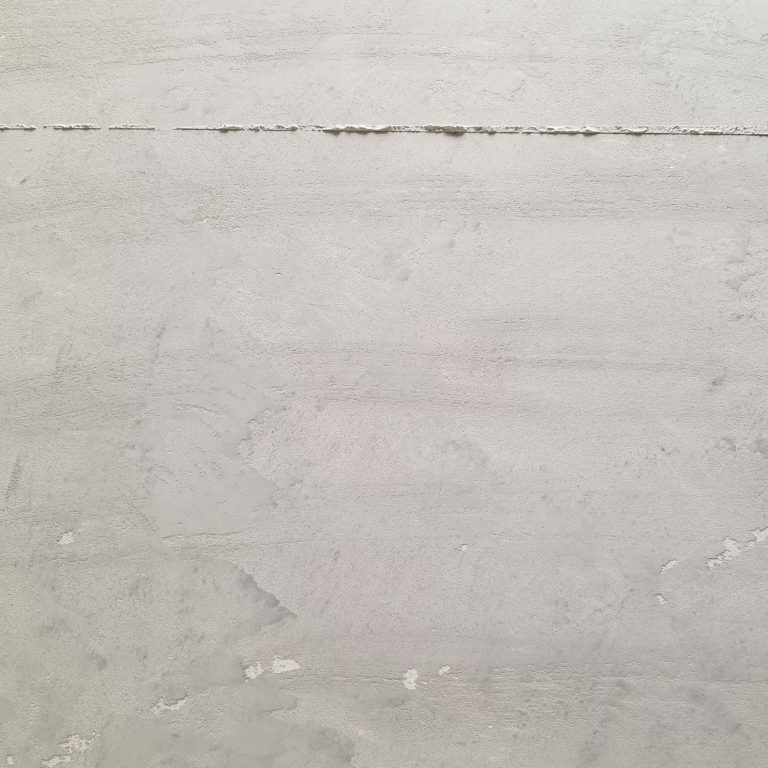

The formulations are developed according to the types of components required and how they can be combined for the custom finish. Creative possibilities range from sealers durable enough for aircraft hangers, to specialized German epoxy primer for tiles, and American-made Microcement. It could mean crafting a wall finish with our Canadian lime and marble aggregate, European additives such as Dutch stone fibers to create a specially crafted plaster for your new restaurant which cannot be duplicated. We can formulate finishes that dry quickly, creating mottling and more dry lines, or plasters that wet out for hours to produce a monolithic finish. We love to take our clients’ ideas and vision and get creative!

Samples

When you receive our original quote, it will include design fees for four 12 x 12 inch samples for each formulation, color, sealer etc. This allows the varying subtleties of each finish to be observed, and to explore how our client is feeling about its effectiveness. We deliver the samples to local designers or builders to review, and modifications may be made at this stage to any of the components to find the desired brand image. There may be extra costs for larger samples (24 x 24 inch), extra modifications, and for samples which need to be shipped outside of the Greater Vancouver Area or internationally, according to where the design firm is located.

Site Planning and Strategy

Once the sample and system are approved, the site planning becomes our next concern. We need to work very closely with the project manager and site supervisor to find the best site outcomes, perfect substrate preparations, and clean work environments. This ensures our ability to meet tight deadlines, have enough dry time, and see that all areas of the project are prepared.

Application

Seeing the finish applied is the most rewarding part of our job. With efficient site planning, most of our projects do not take more than 10 days, and do not disrupt the work flow of other trades. We are aware that Artisans may sometimes be viewed as slow and obsessive of their work, but we like to spend our time before the installations obsessing over the details! It is also common to do site draw downs of the final color to make sure we are as close as possible to the sample color. These finishes are hand-done and naturally vary slightly wall to wall. We make all possible efforts to ensure uniformity among natural materials and on differing surface substrates.